The manufacturing sector stands on the brink of a new revolution, driven by Artificial Intelligence (AI). This technological advancement is not just reshaping the way products are made but is also redefining the very essence of manufacturing processes. Here we aim to unveil the up and coming trends and transformations AI promises to bring to the manufacturing industry and how you can benefit from them, today.

AI: Reshaping the Manufacturing Landscape

AI is rapidly becoming a cornerstone in manufacturing, offering innovative solutions to traditional challenges and opening doors to new possibilities. The integration of AI into manufacturing processes is not just a leap forward; it’s a necessary evolution for businesses aiming to stay competitive and efficient in a rapidly changing market. Let’s look at a few of the main aspects that are changing with the addition of Artificial Intelligence to our industry.

Predictive Maintenance: A Game Changer

One of the most significant impacts of AI in manufacturing is predictive maintenance. AI algorithms can analyze data from equipment sensors to predict when a machine is likely to fail. This proactive approach to maintenance not only reduces downtime but also extends the lifespan of machinery. For plant managers and engineers, predictive maintenance is a game-changer, ensuring smooth operations and cost savings along the way.

Enhanced Quality Control

AI systems, equipped with machine vision capabilities, are revolutionizing quality control in manufacturing. These systems can inspect and detect defects with greater accuracy and speed than human eyes, ensuring that every product meets the highest quality standards. This level of precision in quality control not only enhances product reliability but also bolsters consumer trust in your brand. It reduces the need for costly human resources in areas that are prone to flaws and mistakes, they are just meant to be robotized and automated and AI is taking this to a new level.

Smart Supply Chain Management

AI is transforming supply chain management by offering real-time insights and predictive analytics. This technology helps in forecasting demand, optimizing inventory, and identifying potential supply chain disruptions before they occur. For supply chain managers, AI is an invaluable tool for ensuring efficiency and resilience in the face of fluctuating market demands. It diminishes the risks for disruptions and all the consequences and time wasted that come out of those.

Customization at Scale

The advent of AI in manufacturing heralds a new era of customization. AI algorithms can efficiently handle complex product configurations, allowing for mass customization at a scale previously unimaginable. This capability is particularly appealing for businesses looking to offer personalized products to their customers without sacrificing efficiency or increasing costs. This scalability is crucial and can open up opportunities that offer a wide range of product variations to a broad market. Give your clients small batches of customized products or even single items without the need for extensive retooling or downtime, thereby eliminating many of the inefficiencies associated with traditional custom manufacturing.

AI-Driven Process Optimization

AI’s ability to analyze vast amounts of data and identify patterns enables manufacturers to optimize their processes continually. This continuous improvement leads to increased efficiency, reduced waste, and lower costs. For operational managers, AI-driven process optimization is key to achieving lean manufacturing goals.

Here is a list of some process optimizations and improvements that leading companies are implementing already:

– Real-time Process Adjustment

– Predictive and Prescriptive Analytics

– Customization of Production Lines

– Employee Empowerment and Skill Enhancement

– Energy Management

– Worker Safety and Compliance Monitoring

– Waste Reduction

– Research and Development (R&D)

– Production Planning and Scheduling

– Product Design and Development

– Staff onboarding and Training

We will discuss those in future articles as each one of them is worthy of more time that we can give it here and now, however we can all agree that there is plenty to talk about, if you have questions we are here to answer them – Book a call with us here.

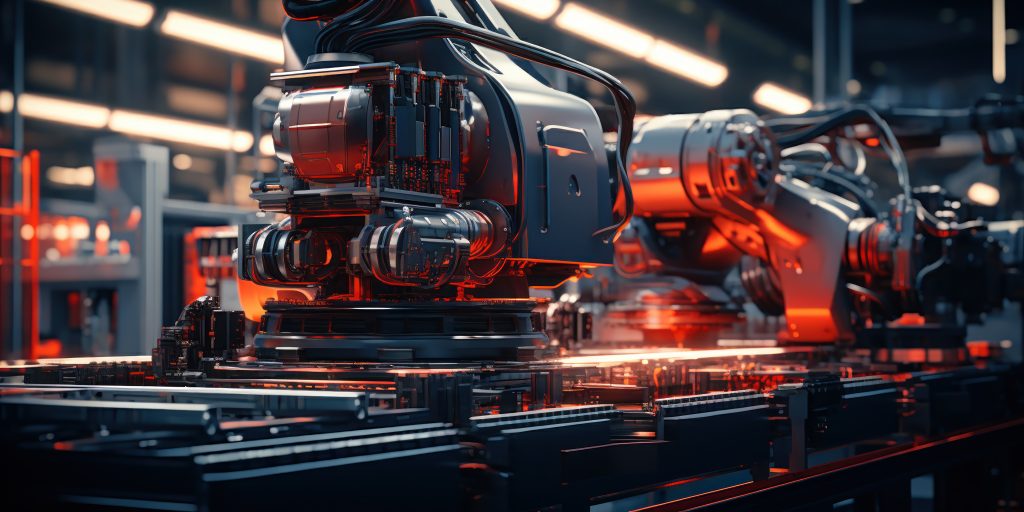

Robotics and Automation

AI-powered robotics are redefining automation in manufacturing. These smart robots can adapt to new tasks, work safely alongside humans, and enhance productivity. The integration of AI with robotics opens up new avenues for automation, especially in tasks that are dangerous or repetitive, thereby improving worker safety and efficiency. AI is giving robots an even better “brain” and the next generation is around the corner. Efficient companies will outperform their competition by a factor of X. The AI race is on!

Sustainable Manufacturing with AI

Sustainability is becoming increasingly important in manufacturing. AI helps manufacturers reduce their environmental impact by optimizing energy use, reducing waste, and improving resource efficiency. This commitment to sustainable practices is not just good for the planet but also appeals to the growing market of environmentally conscious consumers. Policy makers are pushing for harsher regulations, certifications and tax & fees frameworks. AI can help solve those with a fraction of the resources that it would take otherwise.

The Future Workforce and AI

The integration of AI in manufacturing also brings changes to the workforce. AI creates new roles and requires new skills, emphasizing the need for ongoing training and education. Embracing these changes is essential for businesses to harness the full potential of AI in their operations.

Prepare for What’s Next Before It Is Too Late

As the manufacturing industry evolves, staying ahead means embracing AI. It’s not just about adopting new technology; it’s about revolutionizing your processes, products, and business model. We invite industry leaders, operational managers, and decision-makers to discuss how AI can transform your manufacturing processes. Book a call with us today, and let’s explore the future of manufacturing together.

AI is not just a future possibility in manufacturing; it’s a present reality shaping the industry’s future. By integrating AI into your manufacturing processes, you can achieve enhanced efficiency, quality, customization, and sustainability. As your AI development partner, we are committed to guiding you through this transformation, ensuring that your business not only adapts to these changes but thrives in them. Contact us to begin your journey towards an AI-powered manufacturing future.

We understand the complexities of integrating AI into manufacturing processes and offer you tailored AI solutions that seamlessly blend with your existing operations, enhancing efficiency, quality, and innovation. Let’s get ahead of the game, after all, as businesses we are in it to win it! AI can deliver and we can deliver AI. Let’s talk.